Manufacturing Data Exchange Solutions

Advancing the manufacturing ecosystem for resilience, sustainability and competitiveness

Boosting the manufacturing thanks to the power of data exchange

The Manufacturing sector is undergoing a significant transformation, driven primarily by the integration of digital technologies. This shift toward data-centric strategies is impacting nearly every aspect of the industry value chain. The sector’s complexity is further heightened by the presence of a vast number of small and medium-sized enterprises (SMEs), each with varying levels of digital maturity and resources, making the transition both multifaceted and uneven across the ecosystem.

Aiming for more efficient use of resources, optimization of production processes, and the development of smarter, more connected products, the sector also has to deal with the revolution of supply chain management, geared toward more predictive and responsive approaches to inventory control and distribution. At the same time, increasing pressure for transparency and sustainability is driving the need for accurate carbon footprint reporting across the entire value chain.

In this rapidly evolving landscape, Data Exchange is emerging as a transformative force, enabling the creation of robust data ecosystems through secure, compliant, and trusted data exchanges among stakeholders. By accelerating data flows, it fosters data partnerships that span regions, markets, and industries, paving the way for more flexible and resilient production value chains. This shift is fundamentally reshaping how industries interact and collaborate, unlocking new levels of innovation and efficiency.

Bridging industrial challenges with trusted Data Exchange

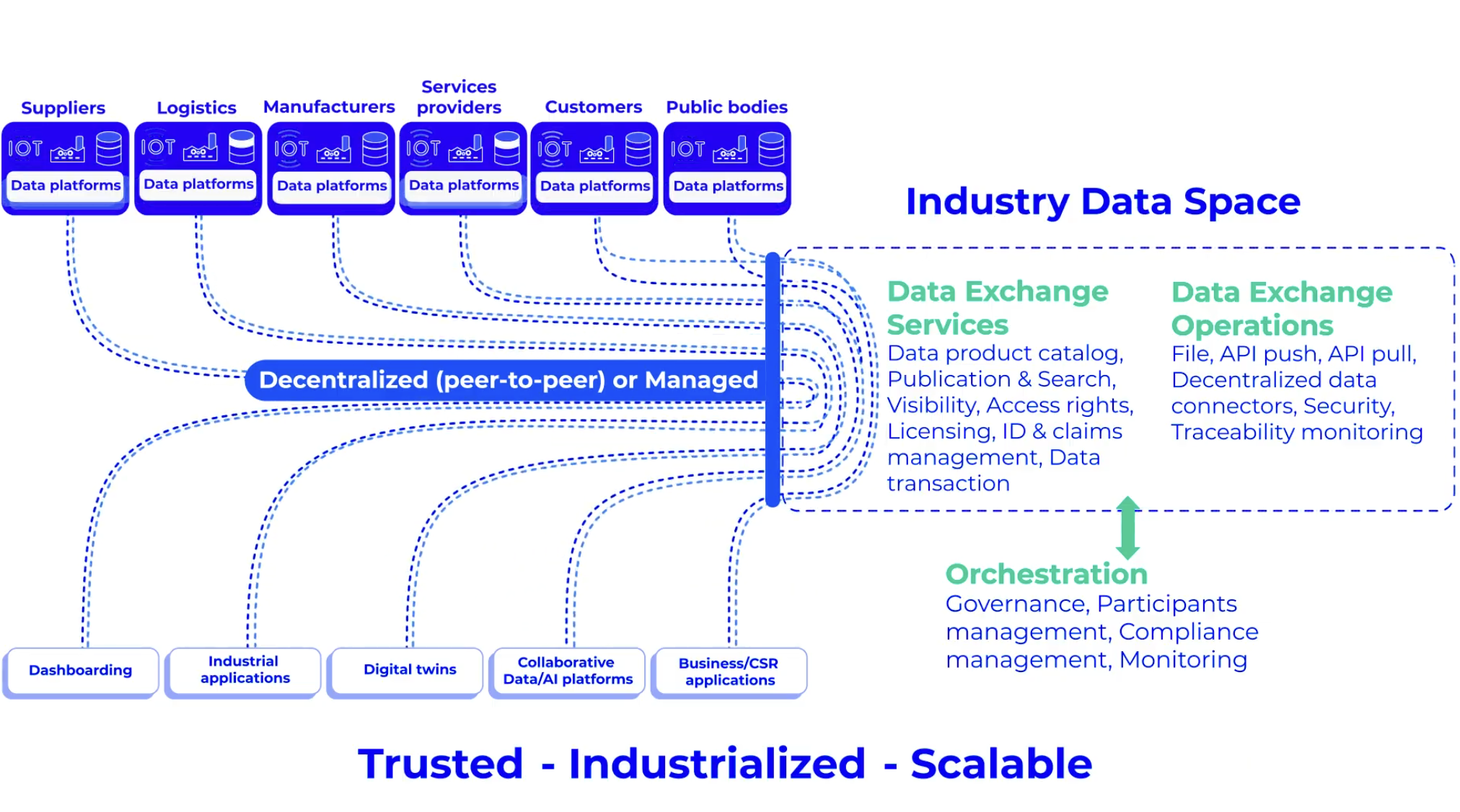

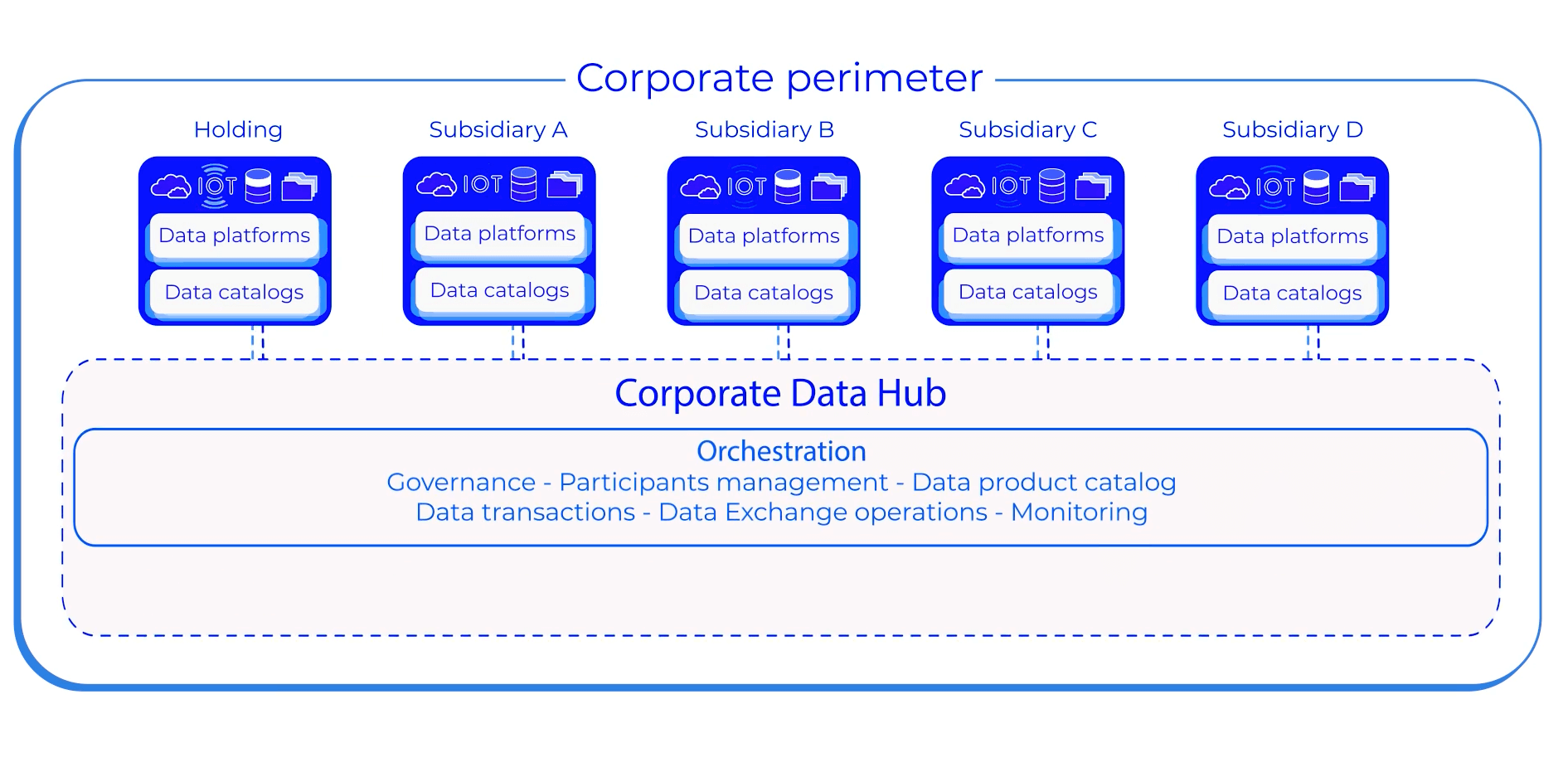

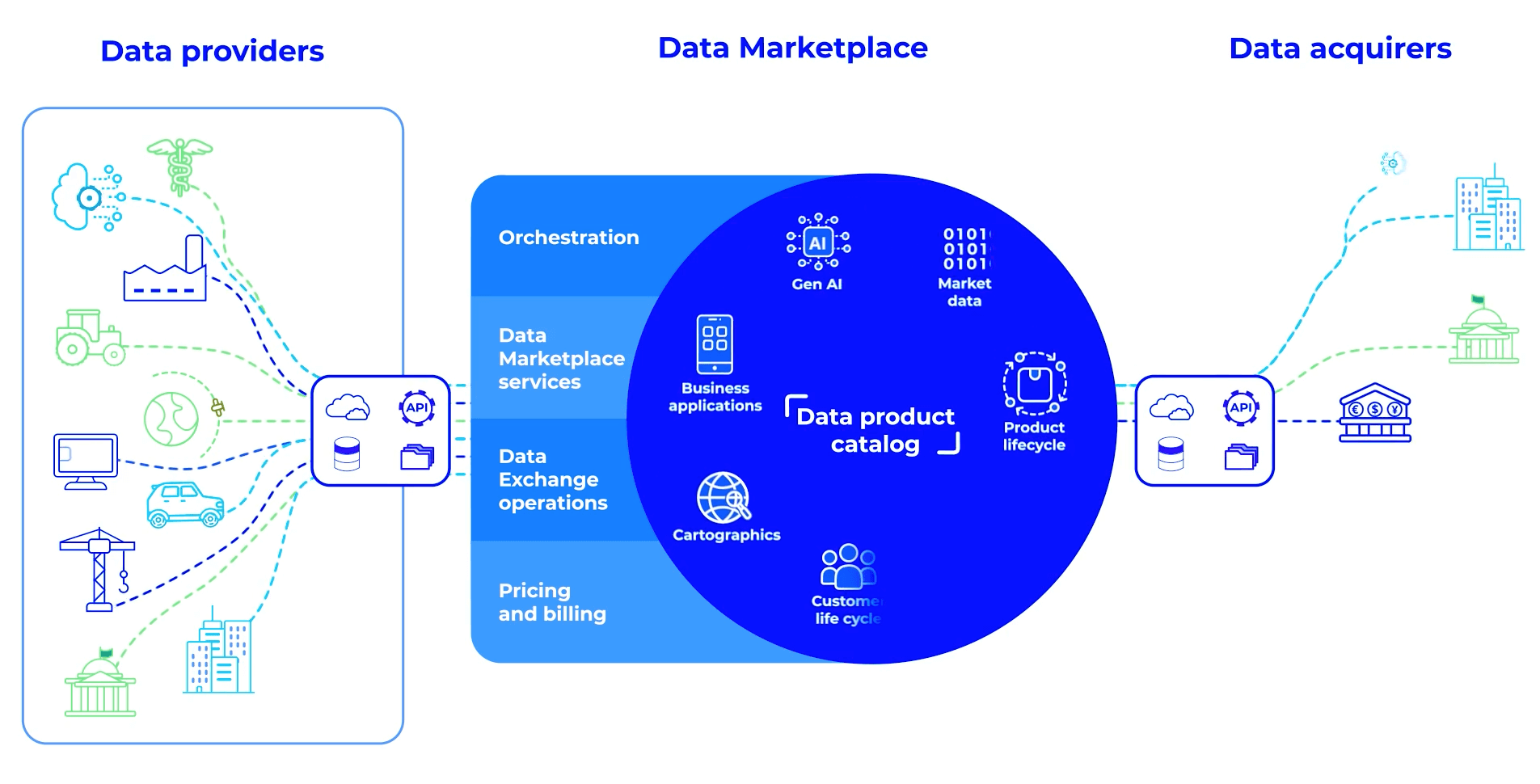

In an environment marked by fragmented systems, strict regulatory requirements, and competitive sensitivities, Data Exchange solutions, such as Industry Data Space, Corporate Data Hub and Data Marketplace, emerge as a key enabler to overcoming these challenges, fostering greater interoperability, compliance, and trusted collaboration across the industrial ecosystem.

Embracing such solutions not only enhances efficiency and resilience, improving the supply chain, but also supports greater innovation, sustainability, and strategic autonomy in an increasingly interconnected industrial landscape.

Insightful stories in the Manufacturing ecosystem

Energy producers and suppliers

Energy producers and suppliers can benefit from leveraging manufacturing & industrial data through data exchange solutions powered by Dawex technology, enabling them to optimize services and better align with manufacturers’ energy needs, such as:

- Tailoring energy solutions by analyzing manufacturing & industrial data to develop customized energy solutions that align with specific manufacturing processes and demands.

- Optimizing supply to adjust energy supply levels more efficiently, reducing waste and costs.

- Predicting needs to anticipate changes in energy demand, allowing for more proactive energy management.

- Enhancing energy efficiency services by providing data-driven advice and services to manufacturers for improving their energy efficiency and reducing their environmental impact.

Transportation & Logistics

Logistics and transport providers can rely on manufacturing & industrial data to enhance their operational effectiveness, improve their supply chain, and align more closely with manufacturing needs, thanks to Dawex Data Exchange solutions in order to:

- Coordinating with manufacturing cycles by utilizing industrial & manufacturing data to align transport schedules with production timelines, ensuring timely deliveries and pickups.

- Optimizing route planning by employing real-time manufacturing data to plan efficient transport routes, reducing transit times and costs.

- Enhancing load management by using manufacturing insights to better manage cargo loads, optimizing space utilization and transport efficiency.

- Improving service reliability by leveraging data to predict potential disruptions and plan contingencies, maintaining consistent and reliable service for manufacturing clients.

Environmental agencies & NGOs

Environmental agencies and NGOs can significantly benefit from manufacturing & industry data. Thanks to Data Exchange solutions. environmental agencies will track environmental impact more effectively and promote sustainable manufacturing practices, by:

- Assessing ecological footprint using manufacturing & industry data to monitor and assess the environmental footprint of manufacturing processes.

- Encouraging eco-friendly practices by analyzing data to identify opportunities for manufacturers to adopt greener methods and reduce waste.

- Improving policy development by leveraging manufacturing data to inform and shape effective environmental policies and regulations.

- Enhancing compliance monitoring by utilizing data to ensure adherence to environmental standards and regulatory requirements.

Retailers

Retailers can harness manufacturing & industrial data through Data Exchange solutions to gain a competitive edge in the market. By accessing detailed insights from the manufacturing process, they can fine-tune strategies for inventory management, customer satisfaction, and operational efficiency—key benefits that stem from secure, real-time data exchange across the value chain include:

- Optimizing inventory by leveraging manufacturing & industry data for precise demand forecasting and inventory control.

- Tailoring product selection by adapting assortments based on manufacturing trends and consumer preferences.

- Offering accurate product information and availability by gaining insight into manufacturing processes.

Investors and analysts

Investors and analysts can leverage manufacturing data to make more informed decisions, understand market trends, and mitigate risks. Thanks to Dawex Data Exchange solution, organizations can access secure, standardized, and real-time data across the value chain, and benefit from:

- Assessing market opportunities by using manufacturing data to identify emerging trends and potential investment prospects in the sector.

- Evaluating company performance by analyzing data to gain insights into operational efficiency, product quality, and market position.

- Predicting industry trends by leveraging manufacturing data to forecast future developments and shifts that inform investment strategies.

- Enhancing risk management by utilizing detailed manufacturing data to better assess and mitigate investment risks.

Want to kickstart, deploy and expand in Manufacturing Data Exchange?

Developing a comprehensive Data Exchange strategy can be complex as it encompasses many aspects. With its multidisciplinary expertise, market knowledge, and proven methodology, Dawex Data Exchange Advisory Services can help your organization identify the opportunities and challenges of data exchange to support your specific needs based on your specific needs and define a customized roadmap to your own Data Exchange Solution.

Benefit from multiple Data Exchange business modelling

Fuel your strategy with the latest on Data Exchange. Subscribe today!

Receive compelling news on data spaces, data ecosystems, data collaboration, and the benefits of Data Exchange in improving competitiveness and driving AI-innovation.